The WEAVER is a new deep learning inference engine that comes with Adaptive Vision Studio 4.12. He is user friendly, cares greatly about performance and reliability. This newsletter will help you to get to know him better.

1- Performance

Deep learning networks are typically created with frameworks like TensorFlow, PyTorch or Caffe. These are great environments for research. However, to achieve the highest possible performance you will also need an inference engine dedicated to your hardware platform. Our experiments have shown that relatively mature and usable choices are: TensorRT (GPU), OpenVINO (CPU), MXNET (GPU), PlaidML (GPU) and ONNX Runtime (CPU). WEAVER is a new option. He works best in machine vision applications and provides state of the art performance on both GPU and CPU.

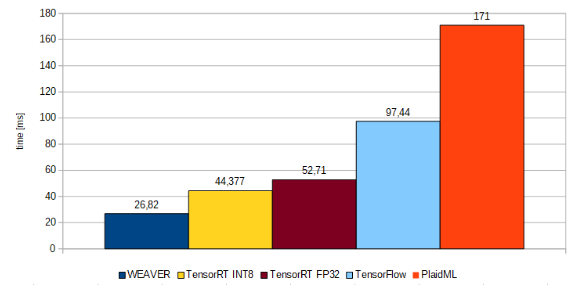

Below you can see how WEAVER‘s performance looks like on our most popular neural network, Feature Detection (supervised pixelwise labeling, Thread Inspection official example):

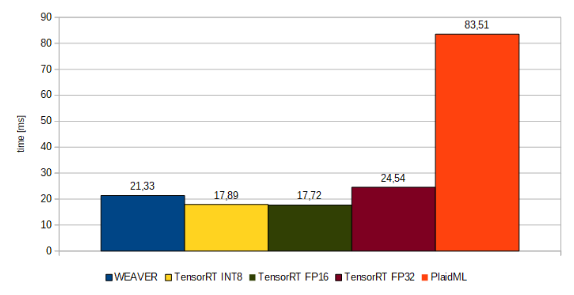

On nVidia RTX 2060, it gets even more interesting. TensorRT can go faster when numeric precision is reduced to 16 bits, while WEAVER still works with full 32-bit precision:

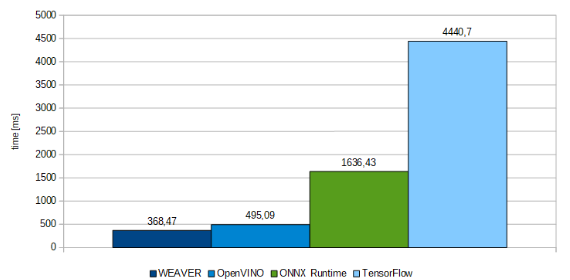

On the Intel CPU platform we compare WEAVER against OpenVINO and ONNX:

DISCLAIMER: The WEAVER inference engine was specifically optimized for neural network we use, including Feature Detection. Performance for other neural network architectures may be different.

2. Reliability

The fast pace of development in the field of deep learning is not particularly helpful in developing real-world systems. Most of our customers require long-term support and stable availability of the components they use. WEAVER solves that. He is independent of the open-source frameworks, eliminates Python code and provides long-term support for commercial projects.

3. Ease of use

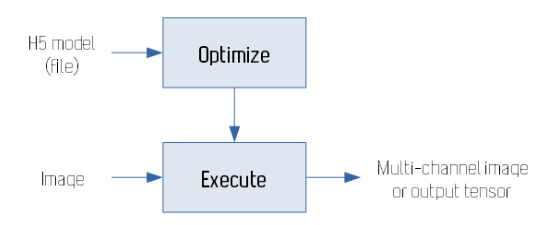

Most of the other inference engines require you to do the Python programming and tweak many things. WEAVER is different. He only does two things: (1) model optimization, (2) execution. All you need to deliver is your H5 network file (Keras output). Moreover, when you create your solution with Adaptive Vision Studio, WEAVER is already employed in three ready-to-use deep learning tools: Feature Detection, Point Location and Object Classification.

DISCLAIMER: TensorRT, OpenVINO, MXNET, PlaidML, ONNX, TensorFlow, PyTorch and Coffe are trade marks of third party companies.

Blog by: Adaptive Vision

Visit FSI Advanced Research in booth # 2605 at SouthTec 2019 to learn about the latest in machine vision technologies, featuring deep learning and 3D. FSI brings the right technology, engineering expertise and advanced analytics to help clients achieve quality performance and experience greater value. Greenville Convention Center, October 22-24. For more information,

Visit FSI Advanced Research in booth # 2605 at SouthTec 2019 to learn about the latest in machine vision technologies, featuring deep learning and 3D. FSI brings the right technology, engineering expertise and advanced analytics to help clients achieve quality performance and experience greater value. Greenville Convention Center, October 22-24. For more information,

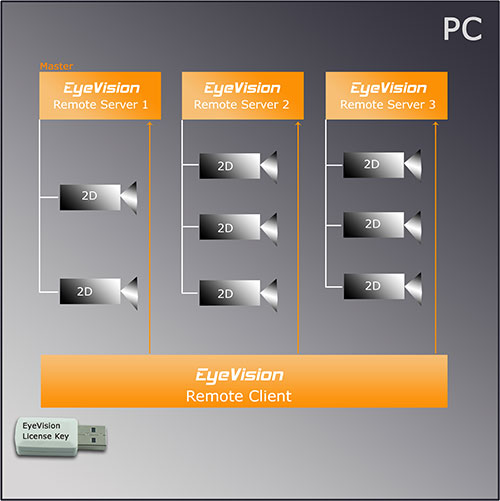

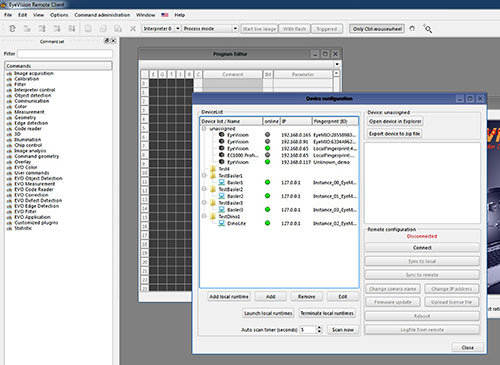

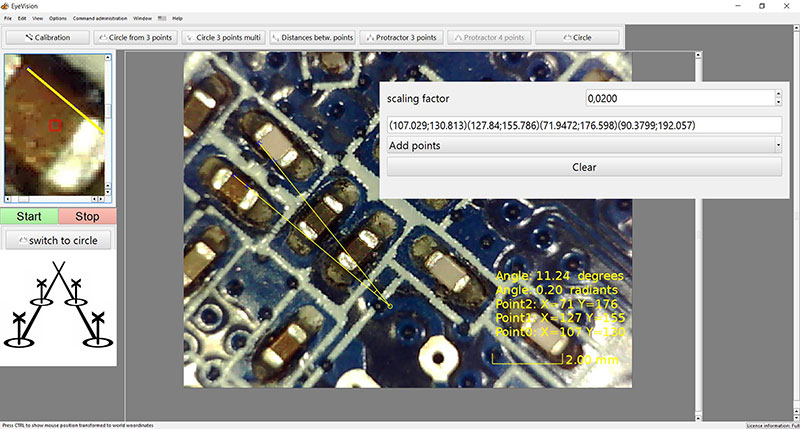

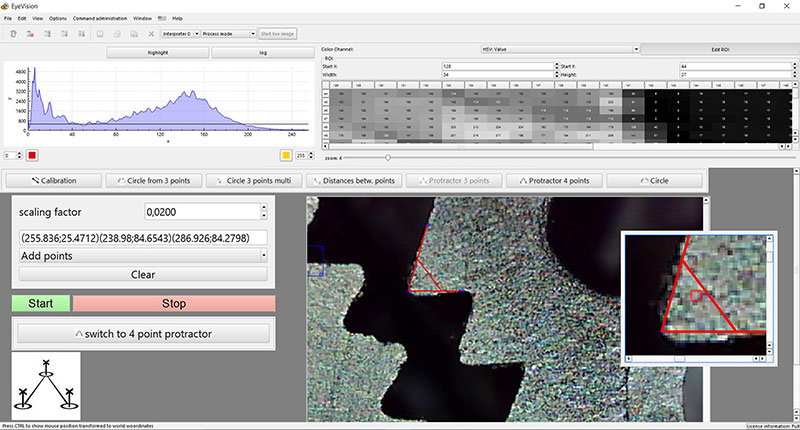

With this function the user might consider using EyeMultiView. It can display up to 16 camera views and evaluation images on one screen. With that many instances and cameras running at the same time, the display functionality of EyeMultiView makes monitoring easier for the user.

With this function the user might consider using EyeMultiView. It can display up to 16 camera views and evaluation images on one screen. With that many instances and cameras running at the same time, the display functionality of EyeMultiView makes monitoring easier for the user. With the Multi-Instance you only need one license for all this. All is now possible with DALSA cameras and as always, the inspection programs can be created with the drag-and-drop function and in the graphical user interface where the user can switch between the different projects and programs.

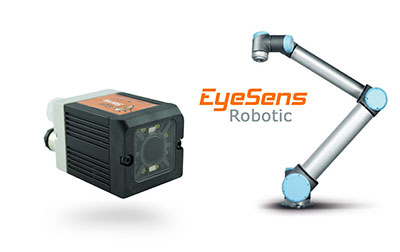

With the Multi-Instance you only need one license for all this. All is now possible with DALSA cameras and as always, the inspection programs can be created with the drag-and-drop function and in the graphical user interface where the user can switch between the different projects and programs. EVT has now added the new EyeSens Robotic to the Smart Vision Sensor System EyeSens.

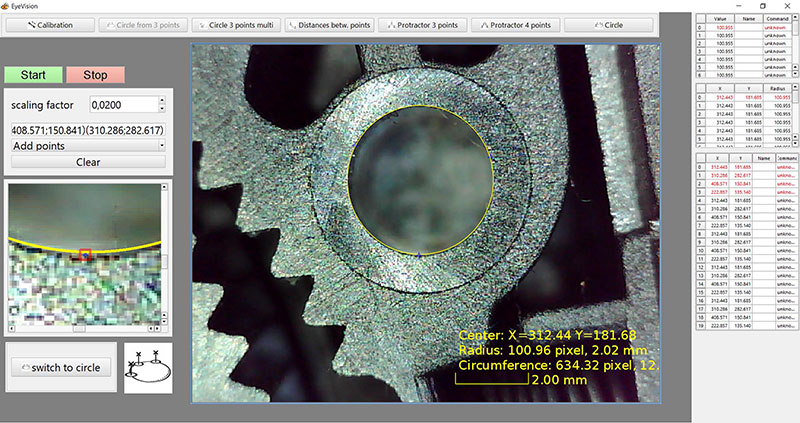

EVT has now added the new EyeSens Robotic to the Smart Vision Sensor System EyeSens. The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands.

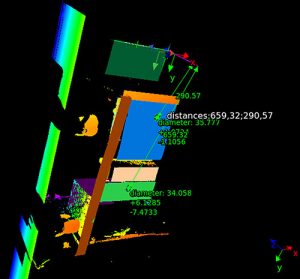

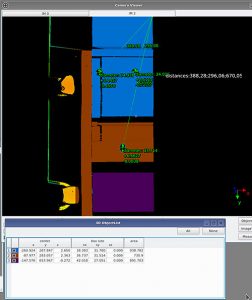

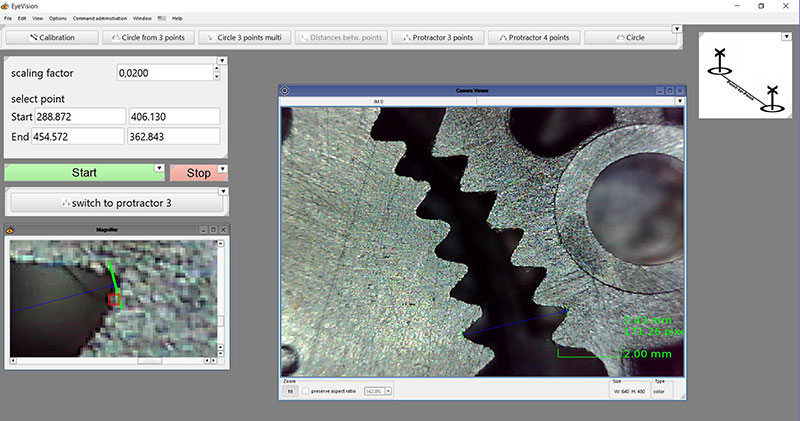

The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands. In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

EyeVision software provides the integrated “brain” of the 3D sensor. EyeVision allows the sensor not only to capture an image but also to use the complete 3D command set of the software to measure, compare and read the 3D point cloud or 2D gray-scale image.

EyeVision software provides the integrated “brain” of the 3D sensor. EyeVision allows the sensor not only to capture an image but also to use the complete 3D command set of the software to measure, compare and read the 3D point cloud or 2D gray-scale image.