Throughout the world robots are used for applications such as packaging, soldering, adhesive bonding, coating, etc. The robots are usually equipped with smart cameras, such as the EyeCheck 1000 series from EVT. Due to the recent advances in image processing, application areas have increased.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

The EyeCheck systems can be used for robot positioning and object detection, custom-made solutions for position correction, and can be mounted onto articulated robots. The moving or stationary objects are illuminated with the camera-based LEDs. Thanks to the robust evaluation algorithms, EyeVision software delivers reliable results even in difficult environments.

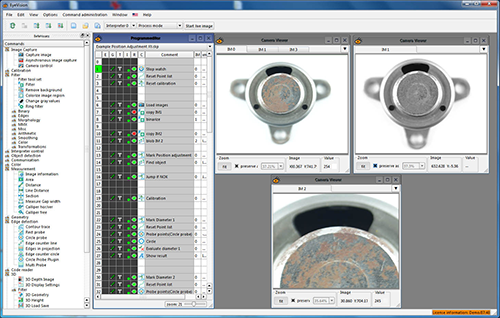

EyeVision software also has commands for code reading, color and surface inspection as well as commands for measuring objects. The system is configured and controlled by the user via the graphical user interface. The drag-and-drop programming allows an easy adjustment to different objects. EyeVision software can be connected to an external computer or the control system of a plant via Ethernet or PROFINET. Applications such as position control can be used in combination with inspection, measurement and identification tasks.