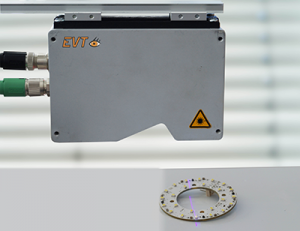

EyeVision software by EVT now also supports a 3D laser triangulation sensor with blue laser. The new EyeScan AT 3D scanner is especially suitable for scanning metal or metallic surfaces.

Today’s noncontact 3D scanners include one of two laser types: blue laser or red laser. Most 3D scanners, including EyeScan 3D scanners from EVT, user red laser technology. The new EyeScan AT 3D Blue, however, utilizes optically superior blue laser technology.

Today’s noncontact 3D scanners include one of two laser types: blue laser or red laser. Most 3D scanners, including EyeScan 3D scanners from EVT, user red laser technology. The new EyeScan AT 3D Blue, however, utilizes optically superior blue laser technology.

The blue-violet Laser has some clear advantages which provide better scan results. Because it has a shorter wavelength than a red laser, a blue laser delivers improved scanning results with higher resolution and up to a 50-percent reduction in data noise. The shorter wavelength creates a smaller laser speckle pattern, generating a sharper depth image. The blue laser is more effective when scanning metal, because a blue laser is narrower and finer than a red laser line.

Thanks to 20,000 profiles per second and the new blue laser, even complex component parts and surfaces can be captured with high accuracy. The extremely fast scans are possible due to the short exposure time and the preprocessing of data with a FPGA inside the scanner. The high dynamic range algorithm with triple exposure makes it possible for dark and bright objects to be inspected in one scan, without a decrease in speed.

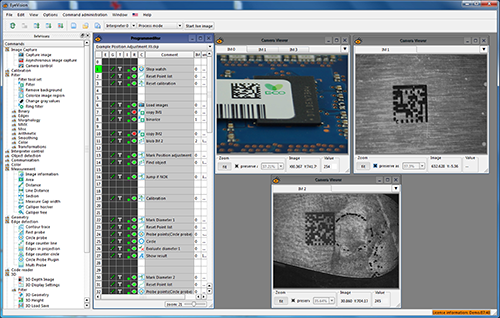

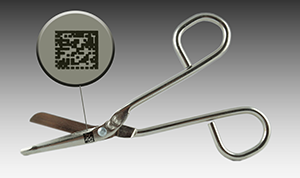

Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality.

Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality. The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.