DALSA Genie camera and many more are now supported by EyeVision

The Genie GigE series and others by DALSA are now supported in EyeVision software.

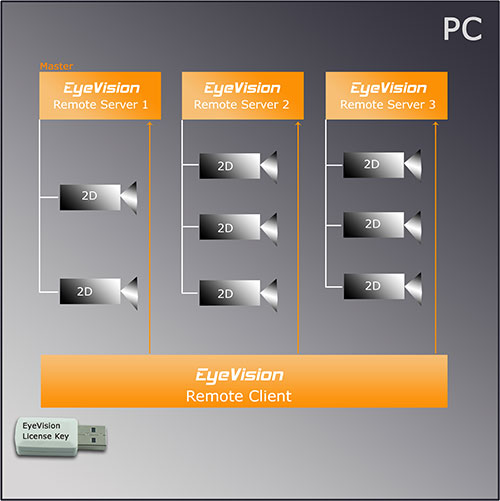

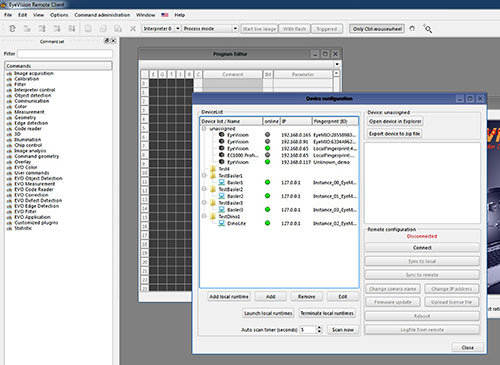

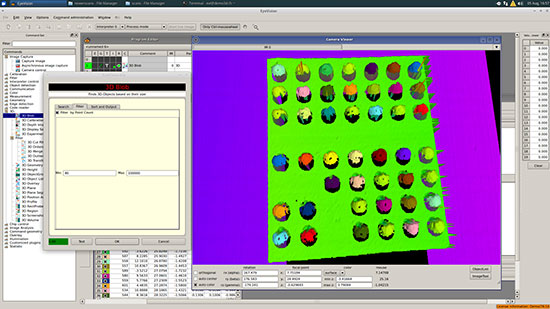

In addition, EyeVision offers a new feature, where with only one instance several cameras or sensors can be operated at the same time. Computers with more than one core can operate more than one camera per instance. The cameras can run different inspection programs but only use one EyeVision license. In short: One EyeVision license, several instances and several cameras per instance. And it does not matter if the cameras have different interfaces (GigE, USB, RS232, etc.), are 2D or 3D cameras, or have color or grey scale sensors.

With this function the user might consider using EyeMultiView. It can display up to 16 camera views and evaluation images on one screen. With that many instances and cameras running at the same time, the display functionality of EyeMultiView makes monitoring easier for the user.

With this function the user might consider using EyeMultiView. It can display up to 16 camera views and evaluation images on one screen. With that many instances and cameras running at the same time, the display functionality of EyeMultiView makes monitoring easier for the user.

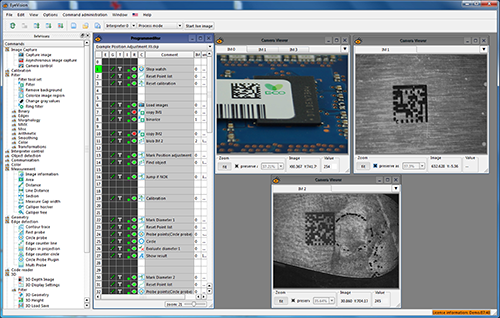

For example, one camera can run pattern matching for error detection on a label and on the second camera the inspection for closed package. On the third camera the color inspection and the fourth one can read the bar code.  With the Multi-Instance you only need one license for all this. All is now possible with DALSA cameras and as always, the inspection programs can be created with the drag-and-drop function and in the graphical user interface where the user can switch between the different projects and programs.

With the Multi-Instance you only need one license for all this. All is now possible with DALSA cameras and as always, the inspection programs can be created with the drag-and-drop function and in the graphical user interface where the user can switch between the different projects and programs.

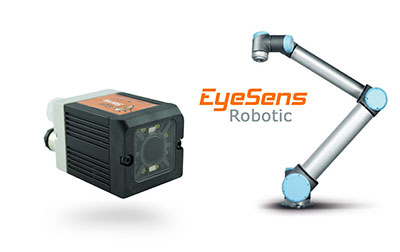

EVT has now added the new EyeSens Robotic to the Smart Vision Sensor System EyeSens.

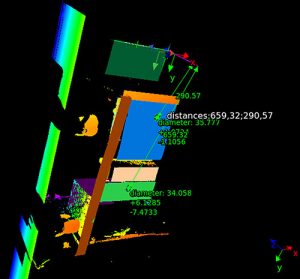

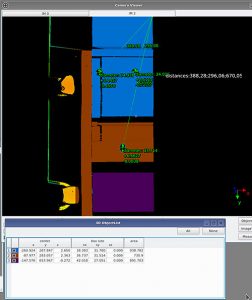

EVT has now added the new EyeSens Robotic to the Smart Vision Sensor System EyeSens. The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands.

The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands. In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm.

The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm. The EyeSens systems from EVT can now also serve as an OPC (Open Platform Communications) server. The OPC standard allows the EyeSens sensors and the EyeVision software to function as OPC server. Detected data such as measured values are now easily sent to a client. The user can determine which data should be sent to the OPC client using the standard interfaces, RS232 or Ethernet. As with other EyeVision software operations, the OPC integration is possible with the drag-and-drop function.

The EyeSens systems from EVT can now also serve as an OPC (Open Platform Communications) server. The OPC standard allows the EyeSens sensors and the EyeVision software to function as OPC server. Detected data such as measured values are now easily sent to a client. The user can determine which data should be sent to the OPC client using the standard interfaces, RS232 or Ethernet. As with other EyeVision software operations, the OPC integration is possible with the drag-and-drop function.

In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.

In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.