The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands.

The measurement of holes and the determination of their position is a special challenge. EyeVision 3D software offers precise 3D measurements with more than 40 specialized commands.

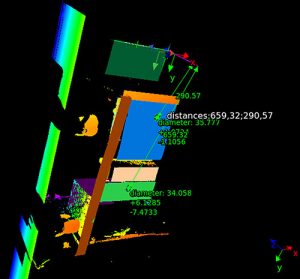

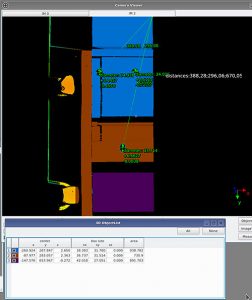

In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

In the case of sheet metal components, it is possible to capture the whole component geometry in a high-resolution point cloud by using visual 3D metrology. A precise metrology command set allows correctly defining various measurements in a point cloud and their coordinates in relation to other results with only a few commands.

Typical characteristics such as hole patterns, cut/trimming, and resilience on edge laps of car bodies can also be measured exactly.

For the inspection of weld seams, as well as adhesive beads, EyeVision 3D software uses the ProfileMatch command. Just a simple parametrization allows the evaluation of profiles and issues an analysis of the detected defect. A detailed protocol for all measurement results can be issued with just a few mouse clicks.

With the complete command set of EyeVision software it is possible to configure the application with 2D cameras and 3D sensors. For example, the point cloud can be displayed as 2½D image, and read an embossed or engraved lettering with a 2D OCR module. This is useful when reading DOT code on a tire or stamped numbers in metal.

EVT image processing software supports various 3D sensors of different technologies, including: AT Automation Technology, Gocator from LMI, Basler ToF, Wenglor, QuellTech, ShapeDrive, Zivid, etc (see table below).

| 3D Technology | EyeVision 3D supported Maker |

| Stereo | RealSense |

| Zivid | |

| Chromasens | |

| Time of Flight | Basler ToF |

| BlueTechnix | |

| Shape-by-Shading | ShapeDrive |

| LMI | |

| Lasertriangulation | AT Automation Technology |

| Wenglor | |

| LMI (Gocator) | |

| VRmagic | |

| QuellTech | |

| 3D cameras | PhotoFocus |

More 3D sensors which will be supported by EyeVision 3D are about to follow.

EyeVision software provides the integrated “brain” of the 3D sensor. EyeVision allows the sensor not only to capture an image but also to use the complete 3D command set of the software to measure, compare and read the 3D point cloud or 2D gray-scale image.

EyeVision software provides the integrated “brain” of the 3D sensor. EyeVision allows the sensor not only to capture an image but also to use the complete 3D command set of the software to measure, compare and read the 3D point cloud or 2D gray-scale image.