EVT, a global player in machine vision technology, announces that the EyeCheck smart camera series now supports PROFINET, a high level network for industrial automation applications. PROFINET defines a network structure for exchanging data, alarms and diagnostics with programmable controllers and other automation controllers on the factory floor. It is the open automation standard for these complex challenges.

EVT, a global player in machine vision technology, announces that the EyeCheck smart camera series now supports PROFINET, a high level network for industrial automation applications. PROFINET defines a network structure for exchanging data, alarms and diagnostics with programmable controllers and other automation controllers on the factory floor. It is the open automation standard for these complex challenges.

PROFINET is compatible with TCP/IP and offers industrial protocols for real time data transmission. The combination of Profinet and EyeCheck smart cameras fulfills all the real-time demands relevant to the automation world, and is well-suited for sophisticated applications, such as those in motion control.

Advantages for machine vision with EyeCheck smart cameras with Profinet include:

- data transmission of high-resolution images over high-speed connections without impacting production speeds.

- the ability to span longer physical distances.

- using point-to-point connectivity over Ethernet hubs.

- allowing manufacturers to remove control systems and PCs from the floor and co-locate them in a controlled environment.

- remote device management which allows tasks on the smart camera (including troubleshooting) to be controlled from anywhere a network connection is available.

The EyeCheck smart camera is a highly integrated optical inspection tool for controlling quality and to increase productivity. It comprises all the elements of an industrial machine vision system in a tiny smart camera style package.

In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.

In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.

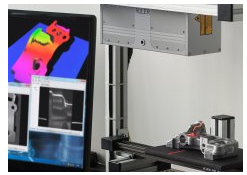

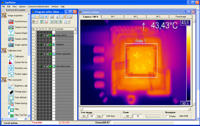

NeuroCheck 6.1, the latest generation of the configurable machine vision software with numerous new features and enhancements, is now available. For the development of 6.1, the focus was on integrating new sensors and camera components, modern communication interfaces and further simplification of operation. For example, sensors are now available that generate a height image using triangulation, a stereo camera or structured light, which can then be evaluated by NeuroCheck 6.1.

NeuroCheck 6.1, the latest generation of the configurable machine vision software with numerous new features and enhancements, is now available. For the development of 6.1, the focus was on integrating new sensors and camera components, modern communication interfaces and further simplification of operation. For example, sensors are now available that generate a height image using triangulation, a stereo camera or structured light, which can then be evaluated by NeuroCheck 6.1. The success story of the NeuroCheck machine vision software began in 1993 with the development and marketing of the first product for industrial image processing on a PC platform where the user is not required to have any programming skills to create an image processing solution. Within an interactive development environment, an entire inspection system can be created and parameterized using various functions without writing a single line of code.

The success story of the NeuroCheck machine vision software began in 1993 with the development and marketing of the first product for industrial image processing on a PC platform where the user is not required to have any programming skills to create an image processing solution. Within an interactive development environment, an entire inspection system can be created and parameterized using various functions without writing a single line of code. EVT EyeVision 3.0 Machine Vision Software now also supports LATAB light controller and lights. The LATAB controllers are microprocessor-based and specifically designed to control all types of LATAB lighting heads.

EVT EyeVision 3.0 Machine Vision Software now also supports LATAB light controller and lights. The LATAB controllers are microprocessor-based and specifically designed to control all types of LATAB lighting heads.

EVT (EyeVision Technology) introduces the new EVOS system for the reading and evaluation of container numbers for the railroad and shipping industries. The system consists of a compact processor unit, which is based on an ARM Technology, and the EVOS reading and evaluation software with integrated SQL database. The system can save and archive not only data but also images of several million containers.

EVT (EyeVision Technology) introduces the new EVOS system for the reading and evaluation of container numbers for the railroad and shipping industries. The system consists of a compact processor unit, which is based on an ARM Technology, and the EVOS reading and evaluation software with integrated SQL database. The system can save and archive not only data but also images of several million containers.

EVT presents the new EyeCheck smart camera with an electrically tunable lens by Optotune.

EVT presents the new EyeCheck smart camera with an electrically tunable lens by Optotune.