These days “Image Processing” is a topic in many industries and it is de rigueur in industrial applications. Hardly a production line can manage without industrial camera and evaluation software such as EyeVision. This also the case with Agribusiness.

One example is the counting of eggs on a conveyor belt. In modern chicken houses to handle this, camera-based systems are installed.

The difficulty here is, that the eggs on the conveyor belt are not in any order and sometimes are touching each other and sometimes not. In this current case the eggs on the image captured by an industrial camera, have to be separated not only from each other – egg between egg – but also from the background. Only then an accurate counting of objects can be guaranteed.

For this the EyeVision uses a series of filters, which allows it to separate and count the eggs under these conditions. Due to the intuitive drag-and-drop programming of the EyeVision software, these filters are easily applied and can be used in other cases, where other similar objects have to be counted.

But before that, there is the question of a suitable illumination or respectively an image, which is high in contrast. Additionally the shadow of the eggs should be as little as possible, as the separation of the eggs from the background and from each other can become blurred. A strong contour is essential to count objects.

For illumination e.g. a back light can be considered. This will have the result, that the eggs appear dark against a bright background. Alternatively the eggs can be illuminated from above with a strong incident light, which will show the eggs bright on a dark background. In both cases a daylight shielding is recommended.

In our case, the second option was chosen – white eggs on black background – where the eggs are also separated clearly from the background. Several different filter commands are needed to separate and count the eggs, which are similar to each other in shape and color. The result are properly separated eggs, as shown in the Camera Viewer of the EyeVision software.

The V3 ring light by EVT is a configurable LED illumination for industrial usage with an RS232 connection. The V3 can display any kind of lighting pattern and can be controlled via a trigger input or optionally via RS232 interface.

The V3 ring light by EVT is a configurable LED illumination for industrial usage with an RS232 connection. The V3 can display any kind of lighting pattern and can be controlled via a trigger input or optionally via RS232 interface.

EVT, a global player in machine vision technology, announces that the EyeCheck smart camera series now supports PROFINET, a high level network for industrial automation applications. PROFINET defines a network structure for exchanging data, alarms and diagnostics with programmable controllers and other automation controllers on the factory floor. It is the open automation standard for these complex challenges.

EVT, a global player in machine vision technology, announces that the EyeCheck smart camera series now supports PROFINET, a high level network for industrial automation applications. PROFINET defines a network structure for exchanging data, alarms and diagnostics with programmable controllers and other automation controllers on the factory floor. It is the open automation standard for these complex challenges. In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.

In Addition to EtherNet/IP, the EyeSens vision sensors by EVT now also support the field bus standard Profinet IO. This allows communicate with both of the most common communication standards of industrial Ethernet.

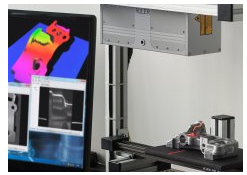

NeuroCheck 6.1, the latest generation of the configurable machine vision software with numerous new features and enhancements, is now available. For the development of 6.1, the focus was on integrating new sensors and camera components, modern communication interfaces and further simplification of operation. For example, sensors are now available that generate a height image using triangulation, a stereo camera or structured light, which can then be evaluated by NeuroCheck 6.1.

NeuroCheck 6.1, the latest generation of the configurable machine vision software with numerous new features and enhancements, is now available. For the development of 6.1, the focus was on integrating new sensors and camera components, modern communication interfaces and further simplification of operation. For example, sensors are now available that generate a height image using triangulation, a stereo camera or structured light, which can then be evaluated by NeuroCheck 6.1. The success story of the NeuroCheck machine vision software began in 1993 with the development and marketing of the first product for industrial image processing on a PC platform where the user is not required to have any programming skills to create an image processing solution. Within an interactive development environment, an entire inspection system can be created and parameterized using various functions without writing a single line of code.

The success story of the NeuroCheck machine vision software began in 1993 with the development and marketing of the first product for industrial image processing on a PC platform where the user is not required to have any programming skills to create an image processing solution. Within an interactive development environment, an entire inspection system can be created and parameterized using various functions without writing a single line of code.