Encoders are commonly used to provide feedback for motor speed control, length measurement and line/product positioning. FSI encoders are built using a rugged aluminum housing that contains precision bearings and electronics. They feature a shaft that protrudes from the side of the encoder. Hollowshaft encoders feature a “hole in the middle” and are mounted over an existing shaft on a motor. A few practical examples for encoder installations are:

- Conveyors

- CNC machines

- Process lines

- Rolling Mills

- Automatic Welding

Applications

Motor Speed/RPM readout – This is one of the more common ways encoders are used. Here, the encoder is mounted onto the end of a motor via a shaft. The encoder’s shaft measures the speed and direction of the motor and provides feedback to the drive. The drive then uses the encoder feedback to accurately control the speed.

Linear Measurement/Cut-to-Length – In this instance, an encoder is mounted onto roller or motor and is used alongside a measuring wheel. The encoder provides a fixed number of pulses in a revolution. A device (such as a preset counter or PLC) is used with the encoder. This device can then deliver a relay or electrical output which operates when the desired length is reached.

Position Measurement – To assess and control positioning (as necessary for a CNC machine or for a programmable limit switch), often an encoder is added to a motor, to an intermediate axle shaft, or both. The important variable in this set-up is incremental movement. Again, a counter, PLC or controller is used. The use of an encoder allows the operator to control both the speed and the position of the parts within the machine.

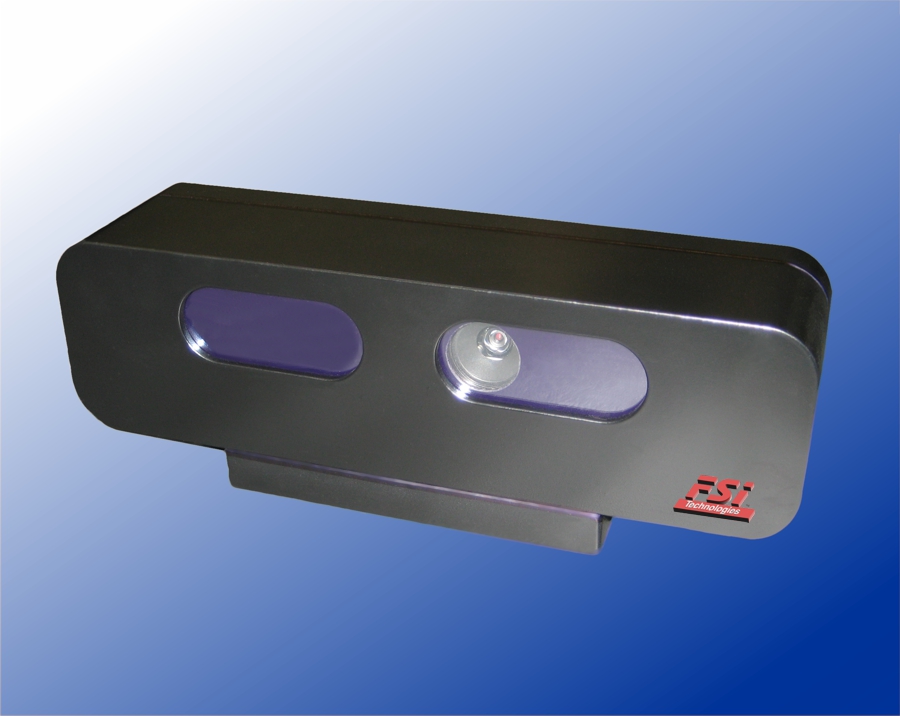

FSI integrates a new 3D imaging sensor into its machine vision product line. 3D sensors provide support to a whole new range of robot control and inspection applications. In some cases, depth sensors can be used alongside normal cameras to support solutions aimed at bin picking, grasping of products through robot control, piloting palettes, sorting products and object recognition. In addition, this technology will aid in determining spatial position, measurements, etc. For more information visit

FSI integrates a new 3D imaging sensor into its machine vision product line. 3D sensors provide support to a whole new range of robot control and inspection applications. In some cases, depth sensors can be used alongside normal cameras to support solutions aimed at bin picking, grasping of products through robot control, piloting palettes, sorting products and object recognition. In addition, this technology will aid in determining spatial position, measurements, etc. For more information visit