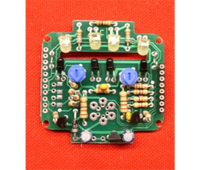

They FyrEye-4003 family of systems inspects assembled circuit boards to ensure the correct components are in the proper locations. It offers the benefits of automated inspection (24/7 operation) and can result in reduced labor costs. Example inspection functions include verifying:

They FyrEye-4003 family of systems inspects assembled circuit boards to ensure the correct components are in the proper locations. It offers the benefits of automated inspection (24/7 operation) and can result in reduced labor costs. Example inspection functions include verifying:

- Presence and correctness of all components

- Quality of soldering

- Component mounting polarity

- Completeness and correctness of mask

- Proper component positioning and orientation/straightness.

- Color codes and labeling

The FyrEye-4003 is a family of systems, customized to your application and requirements. Your particular model will be from the same family, but will have different variations in equipment and capabilities. For more information about the FyrEye-4003 visit http://www.fsinet.com/circuit-board-componentassembly-inspection-systems.htm.

Join the engineers of FSI Technologies Inc. for our next round of Machine Vision/NeuroCheck software training. Classes will run November 5-7th in the western Chicago suburbs. Material covered will include machine vision “basics”, an overview of system hardware, lighting and lens selection, as well as NeuroCheck software tools, programming and example applications. For more information about our seminars contact FSI Customer Service at 1-800-468-6009 or go to

Join the engineers of FSI Technologies Inc. for our next round of Machine Vision/NeuroCheck software training. Classes will run November 5-7th in the western Chicago suburbs. Material covered will include machine vision “basics”, an overview of system hardware, lighting and lens selection, as well as NeuroCheck software tools, programming and example applications. For more information about our seminars contact FSI Customer Service at 1-800-468-6009 or go to  GigE cameras are a global standard in hardware that provide for accelerated image transfer when using basic yet length cables. This unique interface allows for hardware and software from different vendors to function together automatically and successfully. The benefits to this type of connectivity are:

GigE cameras are a global standard in hardware that provide for accelerated image transfer when using basic yet length cables. This unique interface allows for hardware and software from different vendors to function together automatically and successfully. The benefits to this type of connectivity are:

As expected, due to its modern software architecture, NeuroCheck 6.0 installs and runs smoothly on Windows 8. As on Windows 7, it shows good run-time performance and RAM requirements.

As expected, due to its modern software architecture, NeuroCheck 6.0 installs and runs smoothly on Windows 8. As on Windows 7, it shows good run-time performance and RAM requirements.