Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality.

Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality.

EyeVision software can read markings such as:

- alphanumeric characters such as serial numbers, date specification, etc.

- complex codes such as bar codes, 1D and 2D Data Matrix Codes (DMC)

- company and brand logos

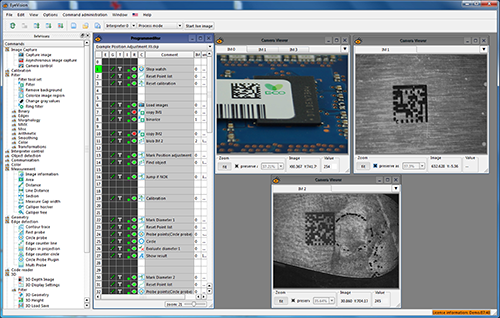

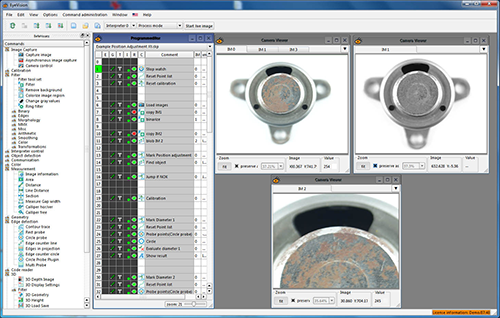

EyeVision software inspects the markings, ensuring consistent quality. Also, the contents of the codes can be inspected. The software includes commands for code reading as well as pattern matching, position, and measurement technology. This is especially important as the code is used for the product identification, traceability, product safety and quality.

The EyeCheck smart cameras are available in various variations and can be equipped according the production process and production line, with diverse sensors and lenses. All EyeCheck smart cameras have one thing in common: the EyeVision software. The software can be mastered in no time at all without special programming skills. Due to the drag-and-drop function and the self-explanatory graphical user interface, inspection programs can be created easily for reading complex codes and characters.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

The EyeVision 3 machine vision software is more flexible than ever. With the new plugin concept, third party software such as Halcon, Open CV or the Euresys library can be integrated into the EyeVision software library.

The EyeVision 3 machine vision software is more flexible than ever. With the new plugin concept, third party software such as Halcon, Open CV or the Euresys library can be integrated into the EyeVision software library. The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm.

The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm.

As with a building architect, a Machine Vision ArchitectSM is the one professional person who is equipped by education, training and experience to guide you through the design and construction of your vision application.

As with a building architect, a Machine Vision ArchitectSM is the one professional person who is equipped by education, training and experience to guide you through the design and construction of your vision application. EVT presents the new Track and Trace image processing system for the pharmaceutical industry. EyeTrace was developed to prevent forged pharmaceutical products from entering the supply chain and assures the traceability of the drugs.

EVT presents the new Track and Trace image processing system for the pharmaceutical industry. EyeTrace was developed to prevent forged pharmaceutical products from entering the supply chain and assures the traceability of the drugs.

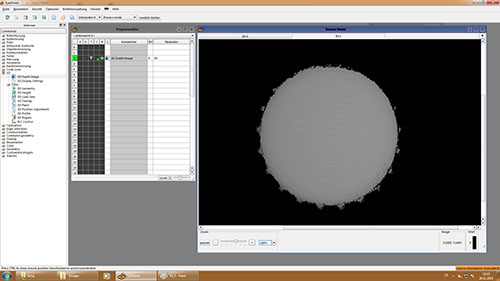

The first intelligent thermal imaging camera – EyeCheck Thermo from EVT – is now available with protection class IP65 or IP67, making it optimally suited for industrial use.

The first intelligent thermal imaging camera – EyeCheck Thermo from EVT – is now available with protection class IP65 or IP67, making it optimally suited for industrial use. The EyeCheck Thermo has eight 24v inputs and eight 24v outputs. By using the additional thermal command set, complex applications for the thermal imaging area can be solved quite easily via drag-and-drop-programming.

The EyeCheck Thermo has eight 24v inputs and eight 24v outputs. By using the additional thermal command set, complex applications for the thermal imaging area can be solved quite easily via drag-and-drop-programming.