Are you looking for a fully-equipped and factory tested machine vision system for experimental use at a reasonable price? The FSI Technologies Inc. Experimental system may be right for you. FSI offers four different models to choose from depending on what software and camera-style you need. For more information on the technical specifications of our systems, visit: http://www.fsinet.com/Express/Express-Experimental-System.htm.

Are you looking for a fully-equipped and factory tested machine vision system for experimental use at a reasonable price? The FSI Technologies Inc. Experimental system may be right for you. FSI offers four different models to choose from depending on what software and camera-style you need. For more information on the technical specifications of our systems, visit: http://www.fsinet.com/Express/Express-Experimental-System.htm.

Category Archives: Machine Vision

FSI Machine Vision/NeuroCheck Training Course

FSI Technologies Inc. will be hosting its Winter 2012 NeuroCheck/Machine Vision training seminar in the western suburbs of Chicago on November 5-6, 2012. This is a 2 ½ day seminar covers courses MVC-101, MVC-102 and MVC-201 and includes topics such as:

- Machine vision technologies, architectures, evolution and purposes

- Tips for successful machine vision project implementation

- NeuroCheck software – tools and usage including:

- Image acquisition

- Presence verification

- Character recognition

- Print quality inspection

- Robot guidance

- Pattern recognition

- Gauging

Class location will be confirmed closer to the date. Please sign up at least 3 weeks in advance in order to secure your spot in the class. For more information about our upcoming training courses visit: http://www.fsinet.com/Training-Overview.htm.

Product News: FSI/EVT EyeCheck Smart Camera

FSI/EVT’s latest Smart Camera, the EyeCheck has a CPU core based on state of the art ARM technology with up to 1 GHz target clock and image processing acceleration by DSP. It has a Linux operating system with GUI. In addition, this tiny vision system has:

- Compact size – card-sized

- Global shutter CMOS and CCD-Sensors

- VGA, WideVGA up to 5 Megapixel grayscale and color sensors

- Memory: DDR Ram 512 MB

- I/O Interface has SPS 2 In/4-Out with option of 4-In/8-Out

- VGA Monitor, RS232, USB 2.0

- Lenses: S-mount with option CS-mount, s-mount or motorzoom

- Illumination: Optional LED ring light in a variety of colors

If you are interested in more information about the EyeCheck Smart Camera, call 630-932-9380.

NEW 3D Imaging Sensor Available

FSI integrates a new 3D imaging sensor into its machine vision product line. 3D sensors provide support to a whole new range of robot control and inspection applications. In some cases, depth sensors can be used alongside normal cameras to support solutions aimed at bin picking, grasping of products through robot control, piloting palettes, sorting products and object recognition. In addition, this technology will aid in determining spatial position, measurements, etc. For more information visit 3D vision System

FSI integrates a new 3D imaging sensor into its machine vision product line. 3D sensors provide support to a whole new range of robot control and inspection applications. In some cases, depth sensors can be used alongside normal cameras to support solutions aimed at bin picking, grasping of products through robot control, piloting palettes, sorting products and object recognition. In addition, this technology will aid in determining spatial position, measurements, etc. For more information visit 3D vision System

“How To” Videos now available for both NeuroCheck and EVT Machine Vision Software

“How to Use the Unroll Tool on NeuroCheck 6.0” – This video teaches users how to implement the “unroll tool”. The “Unroll Tool” is a useful way to take an image of a circular object and turn it into a straight line for easier analysis. One example of an application this tool might be useful for is reading or inspecting text on a wheel. By “unrolling” the object, the text may be easier for the software to find or identify. To watch our latest NeuroCheck Software “How To” video, visit http://www.fsinet.com/Support.htm

“How to Use the Unroll Tool on NeuroCheck 6.0” – This video teaches users how to implement the “unroll tool”. The “Unroll Tool” is a useful way to take an image of a circular object and turn it into a straight line for easier analysis. One example of an application this tool might be useful for is reading or inspecting text on a wheel. By “unrolling” the object, the text may be easier for the software to find or identify. To watch our latest NeuroCheck Software “How To” video, visit http://www.fsinet.com/Support.htm  “How to Use Color Distance and Free Caliper Tools in EyeVision Technology” – This video demonstrates how to use two tools found in EyeVision Technology software – Color Distance and Free Caliper. Color Distance enables users to create a synthetic grayscale image by taking a selected reference color and transforming each pixel to a shade of gray corresponding to the “distance” (in 3D color space) between the reference color and the pixel. This tool can help identify/magnify differentiation between objects in an image. Also demonstrated in this video, Free Caliper is used the same way as a real-life caliper. The jaws of the caliper open and shut and are used to measure a part or product. To view this video, click on http://www.eyespectorus.com/eyevision.html.

“How to Use Color Distance and Free Caliper Tools in EyeVision Technology” – This video demonstrates how to use two tools found in EyeVision Technology software – Color Distance and Free Caliper. Color Distance enables users to create a synthetic grayscale image by taking a selected reference color and transforming each pixel to a shade of gray corresponding to the “distance” (in 3D color space) between the reference color and the pixel. This tool can help identify/magnify differentiation between objects in an image. Also demonstrated in this video, Free Caliper is used the same way as a real-life caliper. The jaws of the caliper open and shut and are used to measure a part or product. To view this video, click on http://www.eyespectorus.com/eyevision.html.

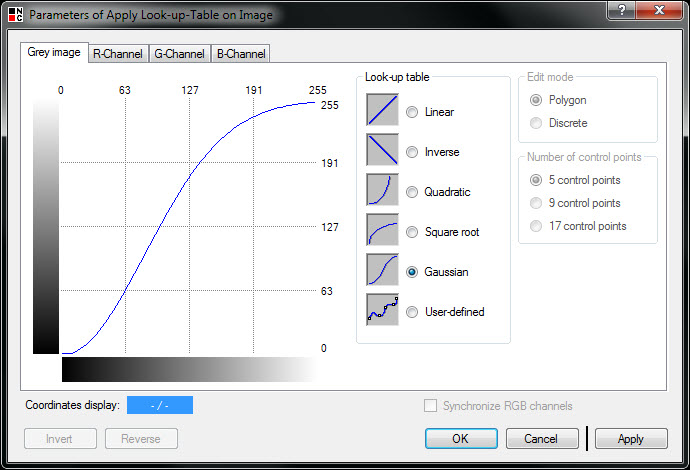

NeuroCheck 6.0: Look-Up-Table Tool

Would your application benefit from an image that has greater contrast? The Look-Up-Table tool in NeuroCheck software transforms the image to create greater contrast in either gray scale or color images. The tool accomplishes this by assigning every gray or color level a new gray or color value. The amount of contrast the look-up table creates depends on the values assigned, either through an existing function or a user-defined function.

For example, we have an image of a car brake assembly with printed text. As you can see in the first image, the printed text is visible but not easily readable. For a character recognition program to better detect the printed text, greater contrast is needed. We can use the look-up table tool to create greater differentiation between the text and the background on this image. On the second image we used the Gaussian function to create sharp transition between dark and light areas (dark areas become darker and light areas become lighter).

|

|

| Before Look-Up-Table Tool | After Look-Up-Table Tool: Gaussian |

NeuroCheck version 6.0 now offers full color capabilities for the look-up table tool (see “Parameters of Apply Look Up Table” image below). Here, RGB values can be modified collectively on color images, or separately using channel controls for each value. Also, the user-defined mode allows the user to define the transformation curve freehand or mathematically.

Variables to consider when selecting the right lens

The choices our engineers have made for our family of CLH lenses help simplify the most difficult aspects of the lens selection process. However, one of the main tasks an engineer will need to do for a successful machine vision system is to establish a proper field of view.

A proper field of view is one in which you can see what you need to see (even if its position changes) and not much more beyond that. It may be a large object that is moving or it may be the details on a product that is stationary. Two variables that you can adjust to change your field of view are:

- Lens Focal length: This is measured in mm (ie: 35mm lens) and relates to the angle of view that will be achieved. Short focal lengths show a wider angle of view, but the objects within that view appear farther off and smaller. Longer focal lengths provide a narrower field of view. Objects within that type of view appear closer and, therefore, larger.

- Distance: This is how far from the object your camera will sit. For some applications, it is important the camera be separated from the product it is imaging. In other cases, the camera can be positioned next to the object being imaged. The farther away the camera sits, the larger the field of view, the closer the camera sits, the narrower the field of view.

The focal length of the lens and the distance of the camera to the object will affect not only what you see in your field of view, but how well you can see it. Adjust as necessary until you find the combination that works for you.

Product News: FSI Machine Vision Lenses

FSI Technologies introduces our newest line of machine vision lenses – CLH Lenses. Hand selected by our machine vision engineers in order to simplify the process, these lenses are versatile and work well with most common machine vision equipment and applications. CLH lenses provide high accuracy and resolution. They can be bought in a variety of focal lengths depending on the needs of your application and are designed to work with high shutter speeds. CLH lenses are robust enough to be used in industrial applications. They are designed with a c-mount configuration and feature dual locking methods and threaded mounts to accommodate filters.

FSI Technologies introduces our newest line of machine vision lenses – CLH Lenses. Hand selected by our machine vision engineers in order to simplify the process, these lenses are versatile and work well with most common machine vision equipment and applications. CLH lenses provide high accuracy and resolution. They can be bought in a variety of focal lengths depending on the needs of your application and are designed to work with high shutter speeds. CLH lenses are robust enough to be used in industrial applications. They are designed with a c-mount configuration and feature dual locking methods and threaded mounts to accommodate filters.

Take the guesswork out of selecting the right lens for your machine vision system and get “focused” on a real vision solution. For more information about our line of Machine Vision lenses, visit

www.fsinet.com/Express/Express-Lenses-Home.htm

press release

FSI Technologies Inc. introduces a line of industrial machine vision lenses, the CLH Series lenses. (press release).

EVT/FSI ChipEye 5 Side

parts, EVT has developed a ready-to-use hardware system, ChipEye 5-Side, which can be built into the machine.

parts, EVT has developed a ready-to-use hardware system, ChipEye 5-Side, which can be built into the machine.

The ChipEye 5-Side can help solve a wide variety of applications by use of its toolset—a group of commands that have been proven to be effective. It is capable of inspecting Pin1, coplanarity, scratches, and more.

With the 5-sided slot in ChipEye, a part can be imaged with the camera and evaluated by the software from five different sides at the same time (top side and four flanks). The robust body of the slot and the powerful 5 Megapixel camera enable it to detect even the smallest defects and to measure finite amounts (e.g. the pin gap accurate to a micrometer).

The function range of the software can be adapted to tasks for a wide variety of applications, so that a special vision sensor for coplanarity is created. This vision sensor can be purchased as a complete system under the name ChipEye Coplanarity.

This system then contains the illumination, the lens andcamera and software. The parametrization of the system is based on an easy drag-and-drop solution. For more information about the ChipEye 5-Side inspection system, contact FSI Technologies Inc. at 630-932-9380 or info@fsinet.com.