Read this informative article on the strengths and weaknesses of using 3D imaging in Machine Vision, written by FSI’s Fred Turek and Kim Jackson. It is featured in the March 2014 issue of Quality Magazine/ Vision & Sensors

Read this informative article on the strengths and weaknesses of using 3D imaging in Machine Vision, written by FSI’s Fred Turek and Kim Jackson. It is featured in the March 2014 issue of Quality Magazine/ Vision & Sensors

Category Archives: Newsletter

FyrEye-3230 Bearing Assembly Inspection System

This system automatically inspects completed bearing assemblies to ensure it is free from defects directly related to final assembly – defects such as:

This system automatically inspects completed bearing assemblies to ensure it is free from defects directly related to final assembly – defects such as:

- Missing or misplaced bearings

- Cage & race damage during assembly

- Reversed orientation of components

- Incorrect components

- Improperly seated bearings

- Race out of round

The FyrEye 3230 is a family of systems, customized to your application and requirements. If you think the FyrEye 3230 is right for you, call us at 630-932-9380.

When A Backlight Isn’t Necessarily A Backlight

FSI engineer Fred Turek discusses alternate ways backlights can be used in an article published in Quality Magazine. To view the article, go to: http://www.qualitymag.com/articles/91209-backlight-basics

FSI engineer Fred Turek discusses alternate ways backlights can be used in an article published in Quality Magazine. To view the article, go to: http://www.qualitymag.com/articles/91209-backlight-basics

Encoder Technical Manual

The FSI Encoder “User’s Manual” is the complete guide to Optical Incremental Rotary Shaft Encoders. The guide contains common output options, wiring information, mechanical drawings for the RSE, HDE and ESE series encoders, and common encoder formulas. The section on encoder theory discusses operation, noise immunity, output options, construction, interfacing, power requirements, mechanical limits, electrical speed limits, environmental limits and maximum line resolution.

The FSI Encoder “User’s Manual” is the complete guide to Optical Incremental Rotary Shaft Encoders. The guide contains common output options, wiring information, mechanical drawings for the RSE, HDE and ESE series encoders, and common encoder formulas. The section on encoder theory discusses operation, noise immunity, output options, construction, interfacing, power requirements, mechanical limits, electrical speed limits, environmental limits and maximum line resolution.

Custom Encoders from FSI

In addition to our standard encoders, FSI can design and manufacture custom encoders to your specifications, for both OEM and specialty applications. Typical customizations include: shaft lengths and diameters; special mounting configurations; various enclosure sizes; different connectors; modified electronics for different output types; enhancements to meet environmental requirements. Call FSI at (630)932-9380 to discuss your custom encoder needs with one of our engineers.

In addition to our standard encoders, FSI can design and manufacture custom encoders to your specifications, for both OEM and specialty applications. Typical customizations include: shaft lengths and diameters; special mounting configurations; various enclosure sizes; different connectors; modified electronics for different output types; enhancements to meet environmental requirements. Call FSI at (630)932-9380 to discuss your custom encoder needs with one of our engineers.

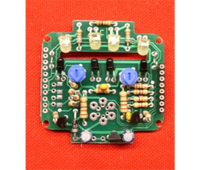

Circuit Board Component Assembly Inspection

They FyrEye-4003 family of systems inspects assembled circuit boards to ensure the correct components are in the proper locations. It offers the benefits of automated inspection (24/7 operation) and can result in reduced labor costs. Example inspection functions include verifying:

They FyrEye-4003 family of systems inspects assembled circuit boards to ensure the correct components are in the proper locations. It offers the benefits of automated inspection (24/7 operation) and can result in reduced labor costs. Example inspection functions include verifying:

- Presence and correctness of all components

- Quality of soldering

- Component mounting polarity

- Completeness and correctness of mask

- Proper component positioning and orientation/straightness.

- Color codes and labeling

The FyrEye-4003 is a family of systems, customized to your application and requirements. Your particular model will be from the same family, but will have different variations in equipment and capabilities. For more information about the FyrEye-4003 visit http://www.fsinet.com/circuit-board-componentassembly-inspection-systems.htm.

NeuroCheck Training in November

Join the engineers of FSI Technologies Inc. for our next round of Machine Vision/NeuroCheck software training. Classes will run November 5-7th in the western Chicago suburbs. Material covered will include machine vision “basics”, an overview of system hardware, lighting and lens selection, as well as NeuroCheck software tools, programming and example applications. For more information about our seminars contact FSI Customer Service at 1-800-468-6009 or go to http://www.fsinet.com/Training-Overview.htm.

Join the engineers of FSI Technologies Inc. for our next round of Machine Vision/NeuroCheck software training. Classes will run November 5-7th in the western Chicago suburbs. Material covered will include machine vision “basics”, an overview of system hardware, lighting and lens selection, as well as NeuroCheck software tools, programming and example applications. For more information about our seminars contact FSI Customer Service at 1-800-468-6009 or go to http://www.fsinet.com/Training-Overview.htm.

More accessories you can use

In addition to wide variety of encoders found on our website, you’ll now find encoder accessories too. Whether you need measuring wheels and chariot mounting systems for measuring, counters to turn the output into motion information (length, speed, position) or flexible couplings to accurately couple the encoder to the machine – the FSI website has it all. For more information about these accessories and more visit: http://www.fsinet.com/ECS-Accessories.htm.

In addition to wide variety of encoders found on our website, you’ll now find encoder accessories too. Whether you need measuring wheels and chariot mounting systems for measuring, counters to turn the output into motion information (length, speed, position) or flexible couplings to accurately couple the encoder to the machine – the FSI website has it all. For more information about these accessories and more visit: http://www.fsinet.com/ECS-Accessories.htm.

Is your maintenance staff still in the dark?

FSI Technologies has shed some light on the problem! The “Indicoder” option is available exclusively on all FSI cube type encoders (ESE, RSE, HDE, etc*). With this option, LEDs are located directly on the body of the encoder that flash as the shaft is turned to instantly verify correct output operation. This indicator will make set-up quick and easy and would also aid in troubleshooting (if that ever becomes necessary). Just ask for the “Indicoder” option when ordering your FSI cube encoder. (*formerly known as Fork Standards encoders)

FSI Technologies has shed some light on the problem! The “Indicoder” option is available exclusively on all FSI cube type encoders (ESE, RSE, HDE, etc*). With this option, LEDs are located directly on the body of the encoder that flash as the shaft is turned to instantly verify correct output operation. This indicator will make set-up quick and easy and would also aid in troubleshooting (if that ever becomes necessary). Just ask for the “Indicoder” option when ordering your FSI cube encoder. (*formerly known as Fork Standards encoders)

GigE – One of the Vision Industry’s current standards

GigE cameras are a global standard in hardware that provide for accelerated image transfer when using basic yet length cables. This unique interface allows for hardware and software from different vendors to function together automatically and successfully. The benefits to this type of connectivity are:

GigE cameras are a global standard in hardware that provide for accelerated image transfer when using basic yet length cables. This unique interface allows for hardware and software from different vendors to function together automatically and successfully. The benefits to this type of connectivity are:

- Highly scalable to work with ever-evolving Ethernet

- Successful data transfer up to 100 meters in length

- Works with cost-effective cables and basic connectors – this translates into

- affordable integration

- Sizeable bandwidth (235 MB/s) enables transfers of large images expeditiously

If you would like more information about GigE camera technology provided by FSI Technologies Inc., call our customer service line at 630-932-9380.