The EyeScan AT 3D sensor – together with EyeVision image processing software can inspect the correct position of pins and check for the quality and position of balls on a Ball-Grid-Array. The connectors of BGAs can be inspected with the 3D sensor for various characteristics up to an accuracy of a micrometer (µm).

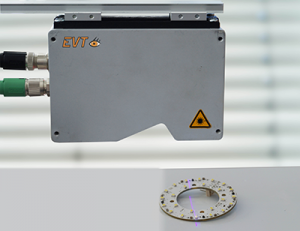

The EyeScan AT 3D sensor – together with EyeVision image processing software can inspect the correct position of pins and check for the quality and position of balls on a Ball-Grid-Array. The connectors of BGAs can be inspected with the 3D sensor for various characteristics up to an accuracy of a micrometer (µm).

Thanks to the Scheimpflug-projection, the laser line stays focused and distortion-free. Even in a high-speed application, the captured images have a high resolution, and no lens distortion correction is needed. Every single bump of the BGA is inspected for its size and shape up to a µm-accuracy.

The EyeScan AT utilizes precision laser line measurement (or laser triangulation). The camera views a laser line, which is projected onto the component (in this case: the BGA) and calculates the height information from the laser line profile.

Utilizing a precision blue laser and on board FPGA the EyeScan AT 3D is capable of over 20,000 profiles per second with very high resolution to capture even the finest details. Additionally, the High Dynamic Range algorithm with threefold exposure allows inspection of bright and dark objects in the same scan without loss of speed.

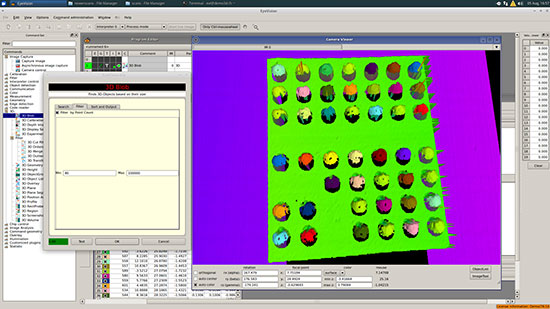

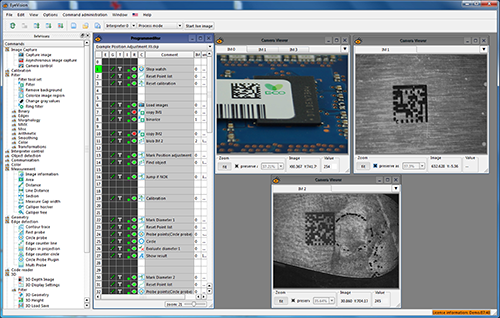

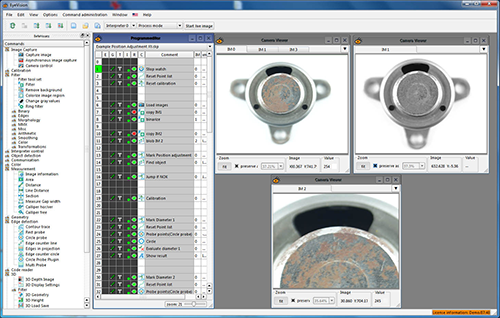

3D image information is processed by the powerful EyeVision software which is programmed though an intuitive drag and drop interface.

Today’s noncontact 3D scanners include one of two laser types: blue laser or red laser. Most 3D scanners, including EyeScan 3D scanners from EVT, user red laser technology. The new EyeScan AT 3D Blue, however, utilizes optically superior blue laser technology.

Today’s noncontact 3D scanners include one of two laser types: blue laser or red laser. Most 3D scanners, including EyeScan 3D scanners from EVT, user red laser technology. The new EyeScan AT 3D Blue, however, utilizes optically superior blue laser technology.

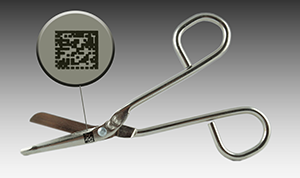

Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality.

Medical products undergo a number of quality and safety inspections and have explicit markings and identification. EyeVision image processing software is often used to inspect markings on medical products. A camera inspection system consisting of an EyeCheck smart camera, which includes EyeVision software, can be integrated permanently into the laser marker head, ensuring an accompanying image capture for verification and validation of the quality. The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

The EyeSens DMC Code Reader from EVT is a compact vision sensor with integrated lens and illumination. There are three different resolutions: 736 x 480, 1024 x 768 and 1280 x 1024 pixels. The EyeSens has a 1/3“ CMOS sensor and interfaces with Ethernet, RS232 and RS422. The lens can be in 6, 12 or 25 mm.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

EyeCheck Smart camera series from EVT offers a combination of a camera and Eye Vision evaluation and processing software. The camera housing contains the lens (the user can chose between 6 mm, 12 mm and 25 mm lenses) and the illumination (available in different colors). The EyeCheck 1000 is available in various resolutions, from 782 x 485 pixel up to 1280 x 1024 pixel, and contains the full command set of EyeVision software.

The EyeVision 3 machine vision software is more flexible than ever. With the new plugin concept, third party software such as Halcon, Open CV or the Euresys library can be integrated into the EyeVision software library.

The EyeVision 3 machine vision software is more flexible than ever. With the new plugin concept, third party software such as Halcon, Open CV or the Euresys library can be integrated into the EyeVision software library. The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm.

The EyeSens ZQ vision sensors from EVT are much smaller than the standard EyeSens sensor. Despite the miniature design, they are powerful, due to the ZYNQ processor with dual Core ARM, and can solve image processing tasks faster than common vision sensors. Because of its small size, light weight and integrated lighting, the EyeSens ZQ is well suited for locations such as a robot arm.